고정 헤더 영역

상세 컨텐츠

본문

I have always placed mine in the flat, not the rib, except for where the two sheets overlap. Going across the 36' width, I place one in each overlap and 2 in the middle, for a total of 4 screws.

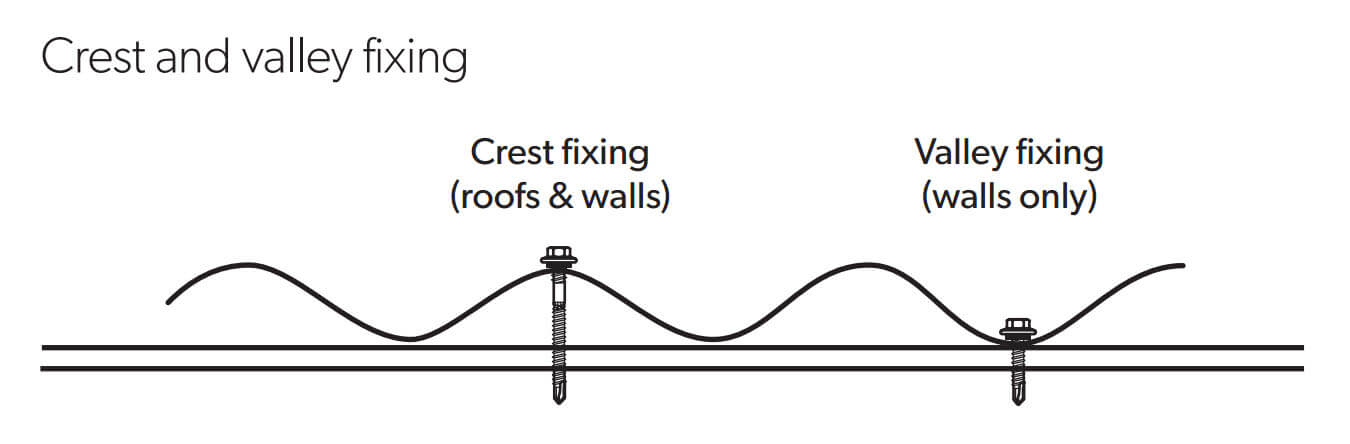

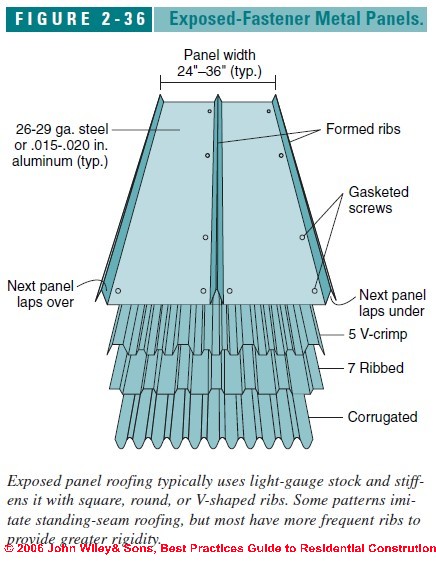

Going up and down the sheet, I try not to go less than 2 feet in spacing nor more than 3 feet, but I've always used lathing spaced 2-3 feet apart.so that kinda' forced the issue for me. If you are placing the metal on a solid surface, you could certainly space the screws closer (but I'm not sure you would need to). Click to expand.That's how I thought it was always done on roofs, unless using steel with the real wide ribs. Less chance of leaks, as the screws sit higher up.FWIW, this was in the Midwest Mfg. (who makes Menards sheet steel) 'how to' book.Note:Both professional and first time installers have fewer problems with oil canning, dimples, and other appearance related fastener seating problems if they install either nails or screws on top of the rib.They left out spacing in the booklet, but since a pole barn the spacing would be 24' max, I might go with that. All of the metal manufacturers will say to put the screws in the flat. I would say the reason is for expansion.

Metal roofs expand and contract quite a bit and you will hear them popping as they heat up and cool down. If you screw in the flat it allows the ribs to absorb the expansion. If you screw in the ribs the expansion will flex the flats lifting them off of the roof.Either way the screws will get loose and the washers will eventually crack or deteriorate. That's the weak link in exposed screw metal roofing.Don't know what type of building you're putting it on but most all metal roof manufacturers recommend sheathing instead of lath. When I put the roof on my cabin, I screwed into the ribs, even though the instructions said to position them at the flats. Roof's been on for 4 years now without a single problem.I used 24' spacing for the screws. Initially, I positioned all the panels by tacking them in place with 1 nail at each corner.

That's important because it is so easy for the panels to become canted and you don't find out till you've reached the opposite side of the roof. Once a whole slope of the roof was in place, I went back, removed the nails, and replaced with roofing screws. Again, starting at the corners, and then filling in at 24' spacing.I would start each hole by punching through with an 8 penny nail, then let the self tapping screws do the rest. Spacing depends on the pitch of the roof. Err on the side of too close rather than too far apart. Caulk or mastic should be used at the lap. Screws are cheap compared to trying to fix a leaking roof and the damage the leak caused.

Give yourself a starter hole and be careful not to over tighten the screw. The rubber washer needs to stay intact to prevent any leak. If you tighten the screw enough to break the washer, you need to replace the screw.Rereading my post, I sound a little to strong to me. This is just my opinion so take it please don't take offense. I have had the displeasure of building quite a few sheet metal structures and these thoughts are just what comes to mind.Doug. One of the neighbors built a home ten years ago.

His contractor said sheathing wasn't necessary, so they just nailed lath up on the roof. Last year a storm came through, and pulled his entire roof off, in one complete sheet.His insurance paid off. But they required a professional put the current metal roof on. With sheathing.I put my screws in between each rib, in the flat, every two feet. Every four feet on the adjoining ribs, along with the 'tape' on each joint. 12 in 12 roof.

15 years, no leaks.My feeling is, if properly installed, on a flat secure deck, screws out on the flats will make a stronger connection than the same screws in the ribs only. More wiggle room for torquing the screws. A screw buried in wood, up to the washer, should be golden. A screw, with an inch to inch and a half exposed, has room for failure.On my next home, I may go with the non exposed screw's type metal roofing. We put our screws in the flat, as recommended by the roof metal mfg.

Installed over purlins, and the screws were placed adjacent to each rib. Purlins distance - I don't know, maybe 16 or 24'.We did not have an issue with leaks at all, for 4 years. Then got hit with a downburst and lost 3/4 of the roof.

Insurance paid for the replaced roof sections, and the only leaks we have now are where the idiot metal building workers either a) missed the purlins altogether b) forgot & put the screws on the ribs or c) overtightened the washered screws.The 1/4 section that is still original does not leak.If you want to do it on the ribs, you will need to get extra long screws so you have enough of the thread secured in the wood. At the fair where I volunteer, the main building(not insulated or heated), built in 78/79 was done by nail on the ribs. We have had leaks in that building since the late 80's, due to the expansion & contraction that comes with cold. A few years ago we had the nails pulled & long washered screws installed.

It's nice now that we don't have to protect the exhibits when it rains! Click to expand.This works well if everything is well aligned or you're going into sheeting.

On our pole barn, the purlins are not perfectly on the same line. Since they were horizontally lapped, they end up one 2x4 width off line, every other 2x4.Two tricks I used was first, getting a good cordless drill. The 18V Dewalt I bought has a hammerdrill feature. Starts the screws without center punching or predrilling.Second, to hit the purlins accurately, I marked the center line on the metal.

Screw Location Metal Roofing

Made up a 2x2 with a nail through the center line on one end. Put the nail end on the 2x purlin/girt. Align the other end's edge with the last screw/nail you put in. Put a mark on the ribs or next to the ribs. Perfect placement in the center of the purlin.What I've read about placement is on the flats for walls, on the rib or flat for roof screws, and on the flats for roof nails.

May be manufacturer specific.Michael.

Metal Roofing

Welcome to Ask the Pole Barn Guru – where you can ask questions about building topics, with answers posted on Mondays. With many questions to answer, please be patient to watch for yours to come up on a future Monday segment. If you want a quick answer, please be sure to answer with a “reply-able” email address.Email all questions to:DEAR POLE BARN GURU: Hi, I wanted to know the best location for screw placement on my pole barn roof. Should I place them on the raised rib or in the lower flat area? WILLING IN WAVERLY DEAR WILLING: Screws should always be placed in the “flat” areas of the steel panels. The first panel will have an overlap on the leading edge (closest to the end of the building). Place a #10 x 1-1/2” screw next to this rib, into a roof purlin, and continue screw placement every nine inches across the roof.

The exception will be at the eave and the ridge, as this is where the greatest shear forces are. At these locations use either a diaphragm screw or a #14 x 1-1/2” screw on both sides of every high rib. Diaphragm screws will have some advantages over the #14 part (and can be used everywhere on the building). They have a narrower #12 shank, other than just below the head, so they are easier to drive and less likely to split the purlins. They also have a ¼” hex head, so driver bits do not have to be switched back and forth.

You can read more about the development of these screws at:Mike the Pole Barn GuruDEAR POLE BARN GURU: I am currently building a pole barn and looking at pricing on an overhead door. Opening is for a 12 x 10. What option do you offer for an overhead door with latch for security? OPENING UPWARDSDEAR OPENING: The options are innumerable.

We offer about every “look” on the market –we’d just need to know what features you want such as glass inserts, designs, etc. Most of our clients use sectional steel doors with inside slide locks. These are available in a commercial pattern (with heavier hardware) as well as numerous profiles of raised panel doors.

If you are trying to create a unique or upscale look, carriage house style doors are also available.In the event you think the building might ever be climate controlled, it is advisable to go with insulated door panels initially, as the cost and effort of retrofitting may prove prohibitive.One thing many people do not consider is wind rated doors. For more information please read:Mike the Pole Barn GuruDEAR POLE BARN GURU: I was looking at the video you have on your site!

I was interested in the 2nd building you showed.the Arena. Was thinking of turning this into a home.